You are here

Home 🌿 Cannabis Technology News 🌿 Cannabis LP from the future built on a farm from the past 🌿Cannabis LP from the future built on a farm from the past

There are a lot of cannabis producers out there using a number of tried-and-true methods, the trick for investors is finding a producer who has a successful operation but also one that is distinct enough that it won't be eventually drowned-out by imitators. A tradition that started on a farm that had been in a family for generations has turned to producing cannabis using advanced techniques also employed by NASA.

A Family Business Moving into the Future

The James E. Wagner Cultivation Corp. (TSX: V.JWCA, OTCQB: JWCAF, Forum) is a cannabis production Company and tech Company that is moving into the future while keeping its family roots firmly in place. This advanced technique is called “aeroponics”, the method of growing plants in an air or mist environment without the use of soil or a similar medium. In an interview with Stockhouse Editorial, Company CEO and President Nathan Woodworth told the story of how his grandfather, James Wagner, inspired the integral part of the Company’s first phase, calling aeroponics “more magic than farming”.

His grandfather had been a farmer for most of his life, from his early 20’s to his late 70’s. He came to work on and manage his wife’s family farm which the family had founded when they came to Ontario from England. Nathan Woodworth spent his summers there as a kid, and it was on the farm that his grandfather taught him how to grow everything from peanuts to potatoes in greenhouses to pastures, even flowers and tomatoes and everything in-between. He was fascinated by all aspects of farming.

Since his grandfather has since passed and cannabis is recreationally legal in Canada, CEO Woodworth added that James also grew cannabis on the farm. Nathan had learned about the basics, and in 2006 was on disability because of debilitating migraine attacks. He tried a great many pharmaceutical approaches, but none worked. He then turned to cannabis under the supervision of his neurologist and finally found an alternative that offered some relief. In 2007, he was growing medicinal cannabis in his home under the former Marijuana Medical Access Regulations (MMAR) and his grandfather would stop by to offer advice.

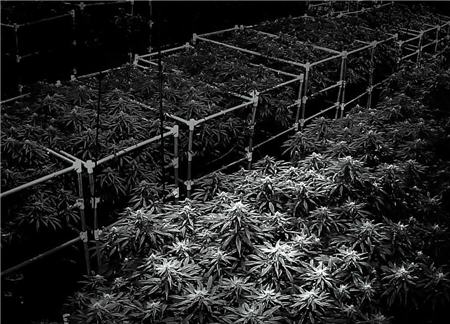

Aeroponically Grown Cannabis

Growing in a completely-controlled aeroponic environment is quite different than growing in a greenhouse. Even a greenhouse is affected by seasons, but in a controlled environment, everything that goes in to growing plants depends on the grower.

During his recovery, Nathan Woodworth became fascinated with the intricacies and possibilities of growing cannabis. When he formed a collective of patients and growers with his brother Adam, who is a PhD candidate in plant biology, they established a number of different sites to study the different methods of cannabis cultivation. They quickly realized that they had run into information barriers. Some of their crops were perfect, while others were far less. They couldn’t put their finger what caused so many differences, so they looked for ways to eliminate all the variables to harness control and understanding of how to build a better system using advanced hydroponic techniques.

Removing the vagaries of soil, nutrients and organic elements, a clearer picture emerged of what is going on within the plant while it is growing. Nathan Woodworth explained that it wasn’t until they began experimenting with aeroponics that they found the perfect solution.

“When you remove the substrate from the plant all together, there’s nothing that encases the roots. All of a sudden, you’re dealing directly with the plant. You can know exactly what the plant is consuming. You can track everything it eats. It got to the point where we could measure the nutrient concentration of a reservoir, the amount of water it consumed, tell you exactly what it had done and eaten on a 15-minute basis, which is really an unprecedented degree of data collection.”

They had all of the pieces of the puzzle in place to move from the MMAR program to the MMPR (Marijuana for Medical Purposes Regulations, now the ACMPR - Access to Cannabis for Medical Purposes Regulation) as a commercial producer. Aeroponics is a technique also used by NASA in space for a number of reasons. Scientists can precisely control the chemistry of the entire system. They bring water and dehydrated nutrients into space, which is cheaper than hauling soil.

JWCA based its system upon aeroponics with a similar mindset. The Company doesn’t bring any contaminates into its workspace - a single gram of soil from outside can contain thousands of different molecular contaminates: from mold spores, bacteria, viruses, insects, insect eggs, even the pieces of the soil itself are physical contaminates in the physical product. None of that is brought into that facility. This means what is grown is much cleaner and more consistent.

Because JWCA is in complete control of their system from top to bottom, the team can be certain there are no additions into the final plant material that weren’t put there intentionally. It can track every molecule that moves into its plants and know exactly, on a molecular level, what those plants are composed of when they’re ready to harvest. The benefit of the system for the consumer? A very high quality product. Management believes the aeroponics produces some of the best cannabis in the world. They expect to be able to grow a product that has 2-4% more cannabinoids by final weight than other producers. This is because the system removes limits on plant growth. This is the key element in its design.

“Always attack the next limit.”

Whatever keeps the plant from growing to its full potential, JWCA removes it. Aeroponics has taken the Company a long way forward to achieving that goal.

Aeroponics is just one method and there are a number of different approaches out there for cannabis cultivation. There are very controlled hydroponic growers, like Organigram. As well as those who use a great deal of expertise and time-honoured tradition in their growing, such as Broken Coast. There are those attempt to look at different ways of cultivating cannabis using other methods of trying to achieve optimization of outcome, such as Green Relief, who use aquaponics, which may sound similar aeroponics, but it is actually quite the opposite. Aquaponics adds fish farming into cannabis, its waste products serve as nutrients. These are slight comparisons to JWCA, but in terms of a direct comparison, CEO Woodworth stated that there isn’t anyone else focused on an end product like this. In working to simplify the system, remove anything extra, what’s left is the best quality output.

Looking at the Company’s output, it is capable of recorded yields of 65 grams per square foot of harvested area of cannabis. It can maintain a perpetual harvest cycle, which means six cycles per year. Nathan Woodworth noted that this is some of the best in the industry for yield per square foot.

In terms of total yield, JWC’s current facility in Kitchener, Ontario is estimated to produce approximately 1200 - 1500 kg of dried cannabis per year now that it is at full capacity. The Company is also in the process of retrofitting a 345,000 sq. ft. building to serve as a new facility just five minutes away from its main operation. This new facility will be able to produce in excess of 30,000 kg per year.

A Consistent Crop

The Company sees immense value in brick-and-mortar stores and is looking at a retail partnership to build its storefront network. It is important for JWC to position itself as a brand of high-quality products that consumers can rely upon.

“If you buy a container of JWC cannabis this time, you buy the same strain next time, you’re going to be getting the same product,” he said. “The same shape of bud, the same size of bud, the same potency, I think there is an advantage of that.”

He feels that cannabis consumers appreciate a level of consistency that alcohol consumers often take for granted, and why wouldn’t they? Every bottle of beer, wine or spirit tastes the same as every other bottle with the same label, so why shouldn’t each cannabis strain be the same produced by a certain brand?

Terpene content, the chemicals that give cannabis its flavour, is a measure of quality. 1% is a good product, 2% is a top shelf product. Most JWC products range between 2-3% and management believes they can push that even higher.

According to a recent Deloitte research report, roughly half of consumers are split between their preference for potency levels of the cannabis they consume, but everyone could agree that consistency is extremely important.

Eyes on the Horizon

JWC began its business as a medical cannabis grower and maintains that as its priority, yet management intends to move into the recreational game, as well as rolling out a line of oils, pending Health Canada approval. As CEO Woodworth explained, the same rules for growing precise medical strains of cannabis apply to recreational strains.

While JWC is a cannabis production Company, it is also a tech Company. Its long-term vision is to develop technologies that would have a profound impact on agriculture in general, beyond cannabis. Its team is working on a feasibility study for a custom-built facility that will be its third facility. This is an extremely large project, one of the biggest of its kind - over a million sq. ft. in size. It is quite distinct in that it will be completely off the grid, using renewable energy sources and all of the advanced techniques they’ve learned over the last 12 years.

This facility can use less than 3% of total water that a commercial greenhouse uses, it will also use lower-cost nutrient. In this facility, management believes it can produce a gram of cannabis for less than 50 cents.

This is significant, because at that price, the equation starts to shift. Other food products could be grown at a reduced cost to what farms are producing. This is a part of the Company’s overall goal, while also being passionate about cannabis, the team wants to change the way people think about agricultural products in general. With this methodology, they could grow any food cheaper and potentially better tasting and healthierthan what is in stores now.

JWC is conducting research into advancements on vertical farming, however CEO Woodworth stated that the technology behind it is underdeveloped. It is still very new and to get the Company to a point where the cost is low enough to make it feasible, more research is still needed. This is where cannabis comes in, to help fund research and development that would not have been possible through other agricultural industries.

Feeding populaces, reducing food shortages and making the world a healthier place, all potentially made possible through a cannabis gateway crop.

420 Intel is Your Source for Marijuana News

420 Intel Canada is your leading news source for the Canadian cannabis industry. Get the latest updates on Canadian cannabis stocks and developments on how Canada continues to be a major player in the worldwide recreational and medical cannabis industry.

420 Intel Canada is the Canadian Industry news outlet that will keep you updated on how these Canadian developments in recreational and medical marijuana will impact the country and the world. Our commitment is to bring you the most important cannabis news stories from across Canada every day of the week.

Marijuana industry news is a constant endeavor with new developments each day. For marijuana news across the True North, 420 Intel Canada promises to bring you quality, Canadian, cannabis industry news.

You can get 420 Intel news delivered directly to your inbox by signing up for our daily marijuana news, ensuring you’re always kept up to date on the ever-changing cannabis industry. To stay even better informed about marijuana legalization news follow us on Twitter, Facebook and LinkedIn.